Some of you may have heard of the die casting process and some of you must be new to this. But we are here to provide information about a topic for everyone. So, moving further with the topic, many of you could assume it to be a dying procedure of clothes, LOL. But it is not. It is something related to metals and molding things into shapes. Let’s begin with some great and unique knowledge. There is a slight difference between die casting and precision die casting. So, we would like to enlighten you with some more details.

What is the difference between die casting and precision die casting?

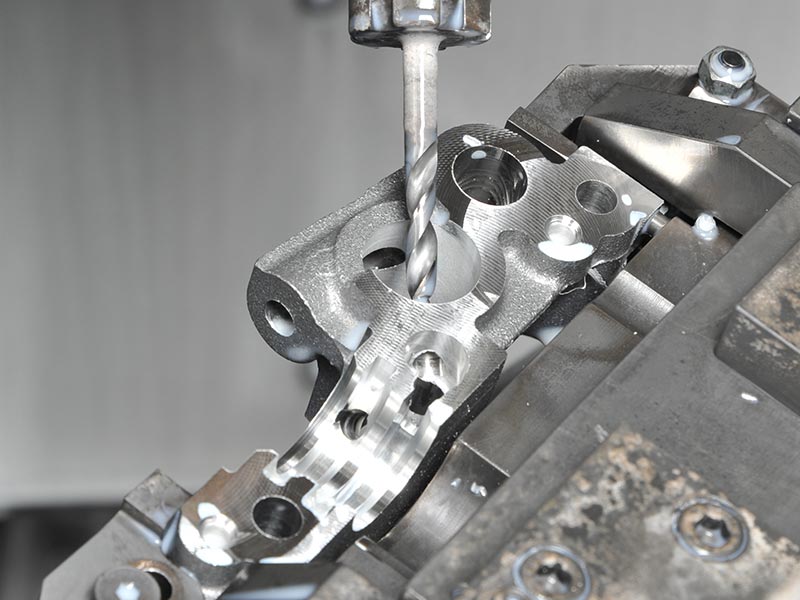

So, Die casting is nothing but what happens in this procedure is that people first melt the metal and then try to mold that metal into a shape or cavity. But in precision die casting, the cavity in which the metal gets molded is made up of 2 steel dies that get created by machines in the desired shape.

How do the die castings are manufactured at EKO?

Die castings are being prepared with metals that are non-ferrous for example, Aluminum, tin-based alloys, and zinc. Also, the metal that is getting used, tells us the machine type to make the cast. The machines are of two types, that is,

- Hot chamber

- Cold chamber

So, In general, die casting is a process that is reliable for items and stuff in a heavy mass because the metal just dies and the equipment that gets used in casting make up a huge part of the main cost or price, and that is why the price of each item is very less. In the process of precision die casting, it has been ensured that the products they’re having must have a great and smooth surface finish and the dimensions must be with correct measurements.

What kind of material is correct for die casting?

The die casting manufacturing process involves materials like alloys that are resistant to corrosion and must have optimum density. The people who determine everything so Correctly like the toughness, hardness, strength and the length, etc are the great engineers that work with them.

There are few very common alloys that get used in the manufacturing procedure,

- Aluminum

- Copper

- Zinc

To meet the requirements of the customer. They also use a varied variety of these alloys for the quality of the product.